Olive Oil Production

The Anagnostopoulos family olive oil production process

01. Hand harvesting

Our extra virgin olive oil is produced by the Anagnostopoulos family, as well as farmers who share our love for the products and the land they grow in, Manesi and Trikorfo in Messinia. We begin with hand harvesting, the most reliable technique. This ensures superior quality from the very first step. The harvest begins in October, and the production process is completed in January. Almost immediately after the harvest, the olives are transported to the olive press for the next stage of olive oil production. Our olive oil is produced with the use of innovative machines by Alfa Laval, which ranks amongst the best in the world. This process ensures its distinguished and rare aromas and a unique aftertaste.

02. Olives’ arrival in the olive oil production unit

A timely start of the olives’ processing, ensure the high quality that defines the Anagnostopoulos family olive oil and highlights the features that make it stand out, its rich fruity taste, low acidity, and high nutritional value. The process begins by placing the olives in the receiving funnel from where they are then transferred with a conveyor belt to the leaf remover unit. The separation of the olive fruit from the leaves, branches, and soil during the reception in the olive mill is done by using air. This process is effective and gentle towards the olive fruit. The olives are then washed with water and then head to the extraction process.

03. Olive oil production of the highest standards

The olives are put in crushing machines, turning into a paste, to move on to the stage of malaxation. Before the crucial stage of malaxation begins, the olive paste goes through Alfa Laval’s Contherm system where with high speed and precision it is heated to 27°C (81°F) in less than one minute with the absence of oxygen contact. Shortly after, the olive paste undergoes the malaxation process for a limited period and with a high-capacity centrifuge. This process ensures that no further pressure or crushing is applied to the olive paste. This is where our company’s innovation comes in. The Anagnostopoulos family was the first one to apply this method after extensive Research and Development. While the traditional method lasted 40-60 minutes, with the Contherm system it takes 30 seconds, and the malaxation process lasts for up to 15 minutes, This innovative approach boosts the olive’s rare aromas and ensures water and energy reduction. Our company focuses on delivering an exquisite product whilst protecting the surrounding ecosystems and nature, by lowering its environmental footprint. This approach leaves a rich legacy for future generations.

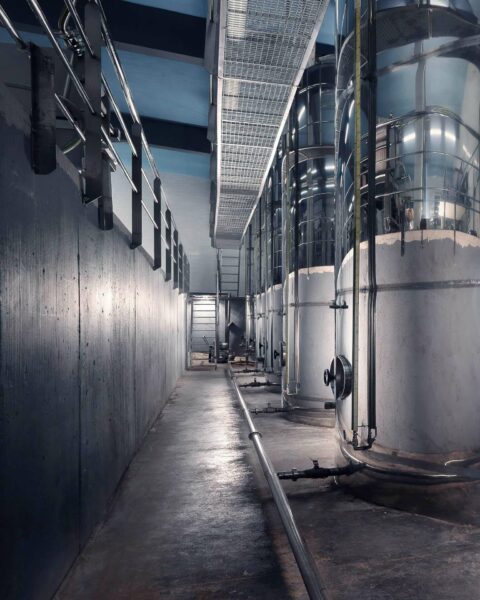

04. Olive oil production & separation

With the process of centrifugation, the olive oil slowly begins to reach its final form. It is separated from the olive paste in two stages. The decanters used by the Anagnostopoulos family for the centrifugation process are amongst the largest in Greece and can fit 15 tons per hour. This ensures maximum efficiency in the olive oil press, protecting its polyphenols. The olive oil is therefore extracted from the olive paste, while the excess liquids are reduced, ensuring the product’s superior quality.

05. Olive oil processing

The olive oil goes through two separators and is isolated from any unnecessary liquids, wastewater, and other substances. This is done with the least possible use of oxygen reaching its clearest form. This top-notch technical expertise results in fresh and quality olive oil in less than 14 minutes.

06. Olive oil quality control

We are committed to producing high-quality olive oil through attentive detail from the very first step to the last. The foundation is, of course, the variety of the olive, the micro-climate, and the terroir of each area in which it flourishes. Furthermore, we ascertain that each olive oil production stage is completed under ideal conditions and that all the procedures and high standards that we have set are followed. Our production process guarantees accuracy and standardized quality. When our product is ready for bottling, we know that it is the best one we could have produced.

We are committed to the production of high-quality olive oil through attentive control from the very first step to the last. It all starts, naturally, from the olives variety. For a superior product, we must look at the olives variety, the micro-climate they grow in, and each area’s soil. As a next step, we ensure that each olive oil production stage is completed under ideal conditions and that all precautions and high standards we have set are followed. When our product is ready for bottling, we know that it is the best we could have produced.

07. Filtering / Storage

The olive oil is stored in underground storage tanks, in clean, dark, and cool storage spaces, with standard temperature and minimum contact with oxygen. We pay attention to every single detail, keeping the olive oil in excellent condition thus maintaining its quality, taste and aromas. This explains why the Koroneiki single variety olive oil has impeccable quality and long-lasting outstanding taste.

08. Bottling / Standardization

It is time for the bottling process, almost immediately after our extra virgin olive oil is transported to the storage tanks. The tanks are carefully designed following strict standards, focusing on automated and controlled bottling and packaging specifications at the Anagnostopoulos family facilities. We use advanced packaging machines to guarantee uniformity and exemplary quality of our olive oil.

09. The future in olive oil production

We stand out for our cutting-edge technology and we are constantly experimenting to perfect them and create high-quality products. The latest addition to our facility in Manesi is the ArcAroma system that will be introduced at the extraction stage. With the use of pulsed electrical technology, we will increase the extraction of oil from the olive paste. Our extra virgin olive oil features the authentic Greek taste and the Anagnostopoulos family quality guarantee We will continue applying new experimental technology and innovative approaches through our partnerships with experts and international organizations.